Multiwire Laboratories, Ltd. offers accessories for use with the MWL120 real-time back-reflection Laue camera system to help quickly align single crystals for orientation

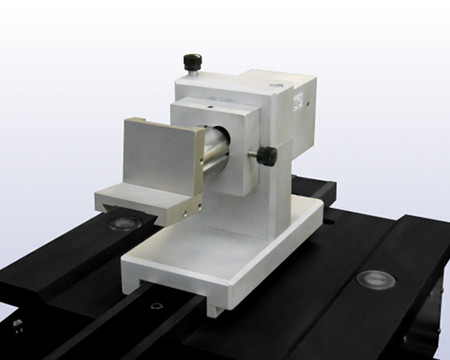

The MWL701A Jack and Translation Stage has been designed for the vertical and horizontal

positioning of crystal orientation devices and samples and will easily support a weight load up to 110 lbs (50 kg).

The MWL701A Jack and Translation Stage has been designed for the vertical and horizontal

positioning of crystal orientation devices and samples and will easily support a weight load up to 110 lbs (50 kg).

Vertical movement is carried out by a rugged jack screw, assisted by two guideposts with ball bearing cages. An independant screw and motor facilitate horizontal translation. The durable aluminum housing features a hard black anodized finish and a 2" wide (50mm) steel mounting track.

The MWL732 6-axis Motor Controller with Joystick is required to operate this stage.

Horizontal range of travel: ~3.9" (10 cm)

Vertical range of travel: ~2.6" (6.7 cm)

| Minimum Step Size | Speed Range | |

|---|---|---|

| Horizontal | 0.003" (0.008 cm) | From 0.003" to 0.1" per second |

| Vertical | 0.005" (0.013 cm) | From 0.005" to 0.2" per second |

The MWL702 Leaded Beam Stop mounts to the X-ray track between the crystal sample and the

operator. The beam stop absorbs and scatters any X-rays that travel beyond the orientation area, protecting

the operator from harm. A thumbscrew secures the beam stop in place.

The MWL702 Leaded Beam Stop mounts to the X-ray track between the crystal sample and the

operator. The beam stop absorbs and scatters any X-rays that travel beyond the orientation area, protecting

the operator from harm. A thumbscrew secures the beam stop in place.

The 6061 aluminium alloy body is painted to match the jack & translation stage, and the lead surface is sealed to prevent skin contact.

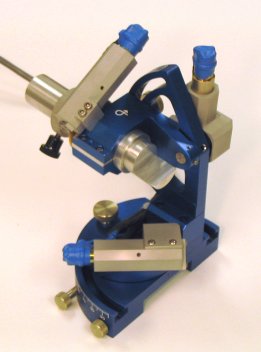

The Motorized Bond Barrel Holder safely supports a crystal sample in the X-ray beam while the

operator adjusts pitch and yaw remotely using a joystick.

The Motorized Bond Barrel Holder safely supports a crystal sample in the X-ray beam while the

operator adjusts pitch and yaw remotely using a joystick.

Once the sample is oriented, the Bond barrel holder can be disengaged from the orientation base by loosening the two horizontal thumbscrews on either side of the barrel holder. The barrel holder can then be mounted in a V-block (not shown) and bathed by a water-cooled diamond saw or immersed in oil during electrical discharge machining as the surface is cut along the oriented plane that is perpendicular to the barrel axis. The 3-axis stage can not do this because it has precision electric motors permanently attached that are not designed for such rough service.

Further Product Details:

The motorized base contains two DC-motor-driven Allen wrenches which tilt the front plate about the horizontal and vertical axes. The motors are torque limited to eliminate damage.

The motorized base mounts to the jack & translation's X-ray track (as shown). The spring-loaded and motorized Allen wrenches engage the barrel holder automatically when the Bond barrel holder is inserted into the motorized base. The barrel holder can accommodate crystals to a maximum weight of 2.2 lbs (1 kg) and can tilt the crystal ±7° on both orthogonal axes.

This unit is designed to be operated by the MWL732 six-axis motor controller with joystick, however the crystal can be manually rotated through 360° about the barrel holder axis. A manually adjustable allen key locks the front plate of the barrel holder when orientation has been completed on a crystal. This is the ideal way to mount a crystal in preparation for a final orientation cut on an external saw.

Step Size: 0.04°

Speed: 0.04° to 0.8° per second

The MWL705 Three-Axis Rotation Goniometer allows for remote angular alignment of crystal

samples while the operator remains safely outside the radiation enclosure.

The MWL705 Three-Axis Rotation Goniometer allows for remote angular alignment of crystal

samples while the operator remains safely outside the radiation enclosure.

Operation of the MWL705 3-axis goniometer requires the MWL732 motor controller with joystick.

| Angular Range | Minimum Step Size | Speed Range | |

|---|---|---|---|

| X-Axis | -60° to 60° | 0.02° | 0.02° to 4° per second |

| Y-Axis | -30° to 60° | 0.02 ° | 0.02° to 4° per second |

| Φ-Axis | 0° to 360° | 0.025° | 0.025° to 3° per second |

The MWL710 Base Plate Assembly provides a sturdy, common mounting point for the MWL120 detector

and the MWL701A Jack and Translation Stage.

The MWL710 Base Plate Assembly provides a sturdy, common mounting point for the MWL120 detector

and the MWL701A Jack and Translation Stage.

The aluminum base plate assembly features a hard black anodized finish.

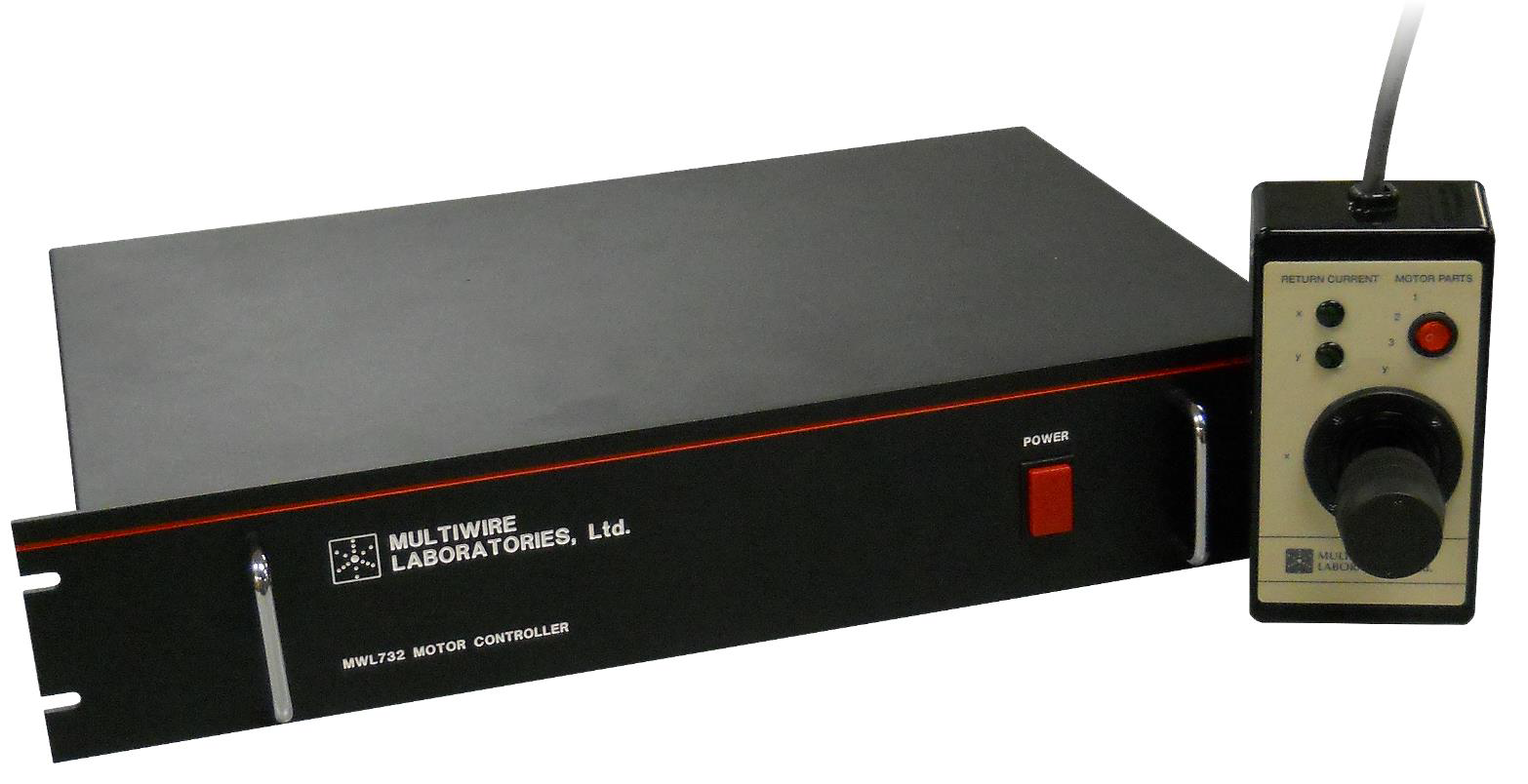

The MWL732 6-Axis Motor Controller with Joystick has 6-axis capability to drive 12 or 24 VDC motors at up to 2 amperes per motor. The joystick controls one pair of motors at a time. The rotary switch allows selection of one of three of the pairs. The motor speed is varied by changing the rate at which full voltage pulses are delivered to the DC motor. This ensures full motor torque even at low motor speeds. LEDs on the joystick indicate the return motor current.